Views: 0 Author: NOVA Elevator Parts Publish Time: 2024-08-13 Origin: Site

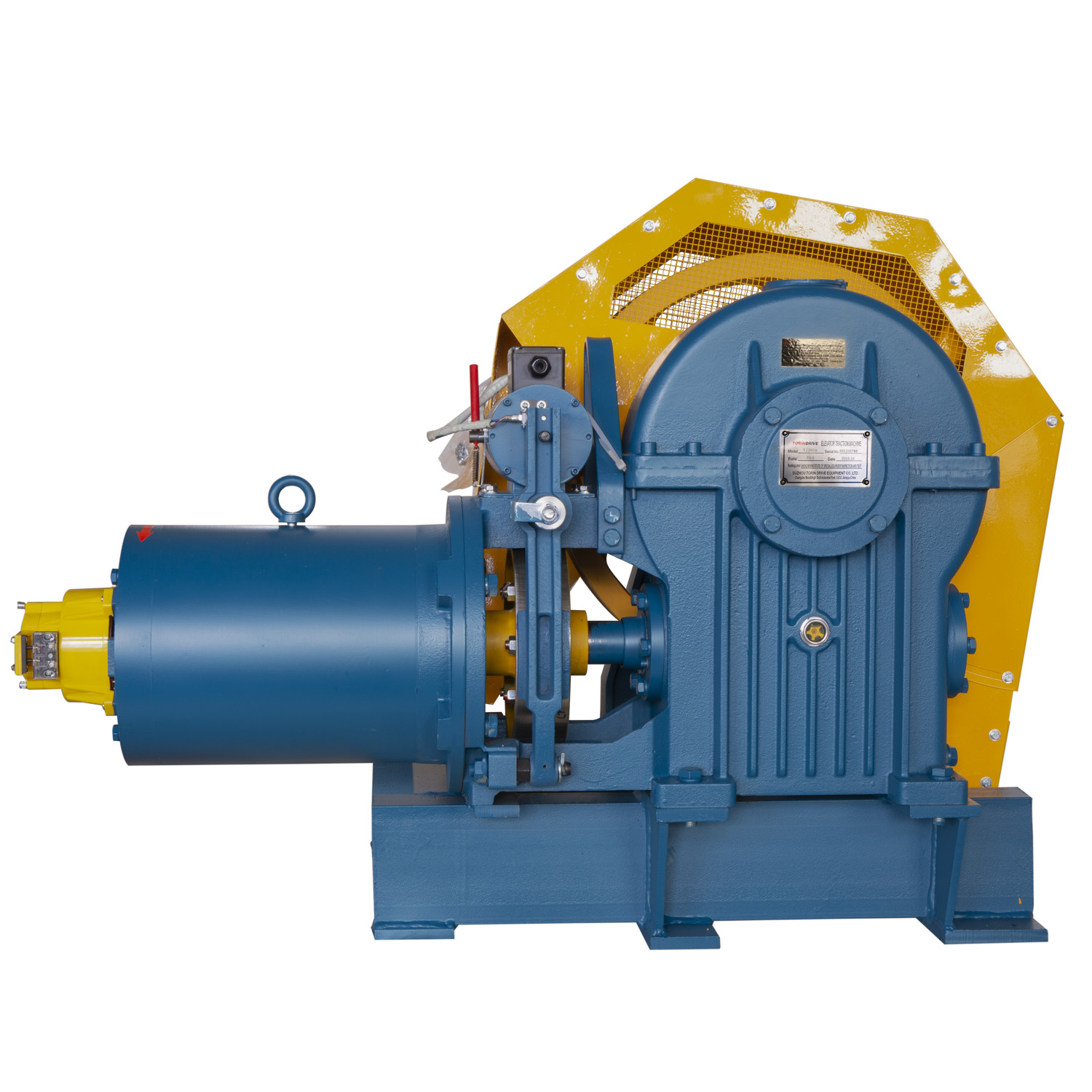

Maintenance and Inspection of Elevator Geared Traction Machines

1.Check whether the elevator geared traction machine is dry and measure the insulation resistance of the winding to the shell with a 500 volt megger. The normal resistance value should be greater than 0.5MΩ. If the value is less than 0.5MΩ, the coil needs to be insulated and dried.

2.The elevator geared traction machine should be cleaned frequently to keep it clean, and check whether there is any debris entering the elevator geared traction machine. However, liquids such as gasoline, oil, or kerosene should not be used to wipe the motor windings.

3.Replace brushes before they wear out.

1.Check the bearing lubrication condition of the elevator geared traction machine, and replenish the bearing grease in time after half a year of use.

2.When the elevator geared traction machine is working, water or oil must be prevented from entering, and the anchor bolts must be strong. The two half couplings connecting the motor and worm must be aligned with the center and cannot be offset.

3.The elevator geared traction machine generally does not make a lot of noise when working. If any abnormal sound is found. Check in time whether the air gap between the stator and the rotor remains uniform. If the air gap difference exceeds 0.2mm, the bearing needs to be replaced.

4.The temperature of the elevator geared traction machine does not exceed 80°C when it is working, and there is a slight and uniform rotation sound. If the inspection finds that the temperature is too high and there is abnormal noise, remove it in time for cleaning and inspection, and refill the engine oil.