Views: 4 Author: NOVA Elevator Parts Publish Time: 2024-09-21 Origin: Site

Elevator Door Operator Failure Causes and Solutions

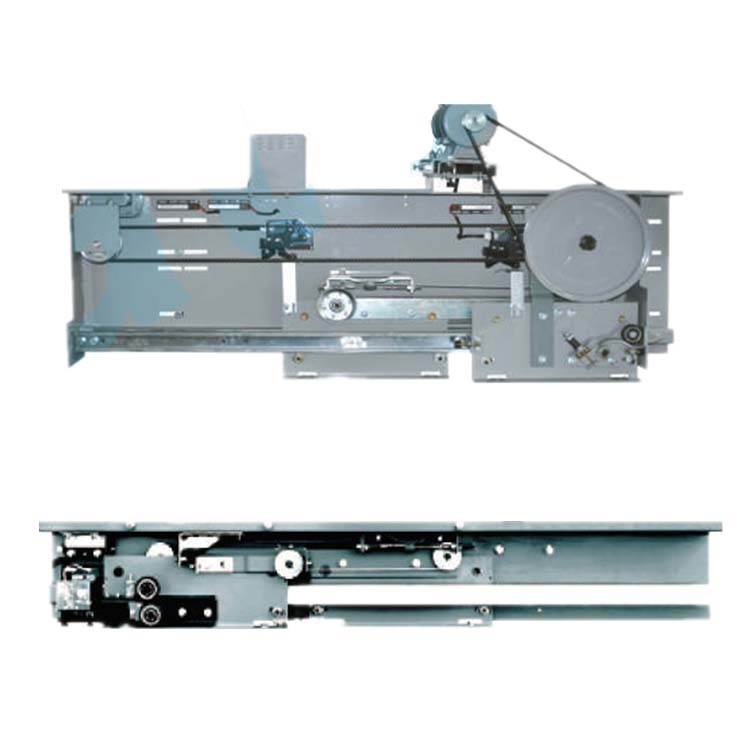

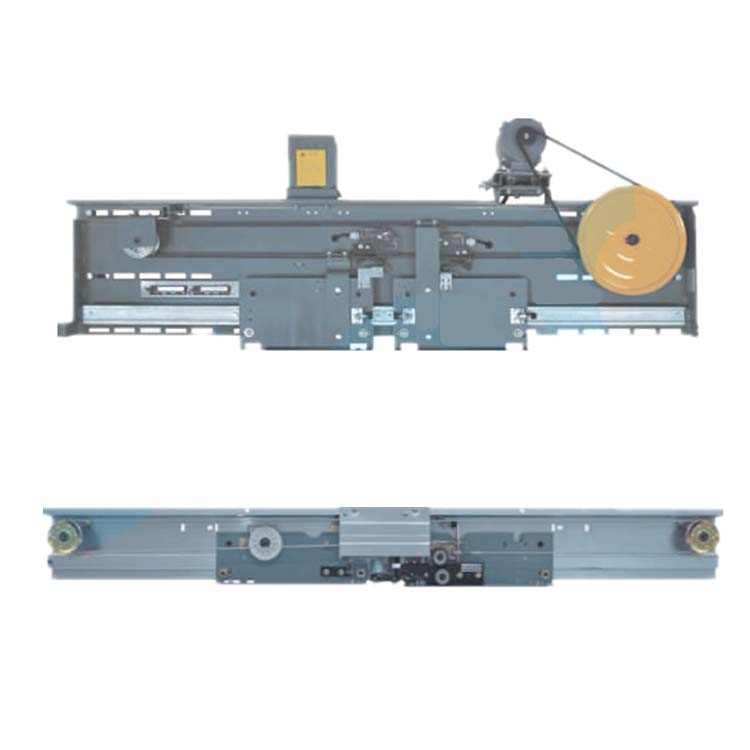

The elevator door operator is a key component that controls the opening and closing of the elevator door. The stability of its performance is directly related to the safety and efficiency of the elevator. Once the elevator door operator fails, it will not only affect the normal operation of the elevator, but may also cause safety hazards.

Common causes of elevator door operator motor failures

1.Overload operation: If the elevator door machine motor works in an overloaded state for a long time, it may cause the motor to overheat or even burn out.

2.Power supply problems: Unstable power supply or voltage fluctuations may cause the motor to operate erratically, leading to failure.

3.Mechanical failure: The guide rails, sliders and other mechanical parts of the elevator door are worn or damaged, which increases the running resistance of the motor and leads to failure.

4.Control system problems: Failures in the elevator control system, such as signal errors or program disorders, may cause the door motor motor to receive incorrect instructions.

5.Environmental factors: Harsh environmental conditions such as high temperature, humidity, and dust may accelerate the aging and damage of motor components.

6.Insufficient maintenance: The lack of regular inspection and maintenance allows potential small problems to gradually evolve into major failures.

Measures to prevent elevator door machine motor failure

1.Avoid overload: Ensure that the elevator door motor motor works within the specified load range and avoid long-term overload operation.

2.Stable power supply: Provide a stable power supply and install a voltage stabilizer or uninterruptible power supply system (UPS) to protect the motor.

3.Regular inspection: Regularly inspect and maintain the mechanical components of the elevator door to ensure its normal operation.

4.System upgrade: Regularly upgrade the elevator control system to fix known defects and errors and improve system stability.

5.Environmental control: Control the environmental conditions of the elevator shaft, such as installing air conditioning or dehumidification equipment to reduce the impact of the environment on the motor.

6.Professional maintenance: Regular inspection and maintenance by professionals to detect and solve problems in a timely manner.

Diagnosis and repair of elevator door machine motor faults

1.Fault diagnosis: Preliminarily determine the cause of the fault by observing the motor's operating status, sound, temperature, etc.

2.Component inspection: Conduct a detailed inspection of the motor and its related components, such as bearings, carbon brushes, wiring, etc.

3.Performance test: Carry out motor performance test, such as current, speed, torque, etc., to ensure that the motor operates normally.

4.Replacement and repair: For damaged parts, replace or repair them in time to restore the normal operation of the motor.