Views: 2 Author: NOVA Elevator Publish Time: 2024-12-13 Origin: Site

Daily Maintenance of Elevators

1.Daily cleaning

The most important thing in elevator maintenance is daily cleaning. Dirt is often the main cause of elevator failure. A little dust on the relay contacts or door locks can stop the elevator from running. Usually potential failure points and worn parts can be discovered through daily cleaning.

2.Replacement and repair of parts

The second most important task of maintenance and care is the replacement and repair of parts. Worn parts must be replaced to ensure the continued safe operation of the elevator and minimize failures.

3.Lubrication

The third most important thing is lubrication. For any mechanical equipment, proper and systematic lubrication can reduce wear to a minimum, ensure the normal operation of the elevator and extend the life of components.

4.Adjustment

Finally, adjustment is the process. It is just as important as keeping the elevator clean and lubricated, and is one of the most important elements to ensure that the elevator is in optimal condition.

Even if an elevator is kept clean, all parts are well lubricated, and worn parts are replaced in a timely manner, if the adjustment is not appropriate, the purpose of the entire maintenance cannot be achieved.

Main inspection items of elevators

1.Check and adjust the engagement condition of the hall door lock

Check whether the engagement distance between the hall door lock hook and the electrical contact is more than 7mm and the compression stroke of the contact. If it does not meet the standard requirements, adjust it.

2.Manual winching operation

Before manual winching, the main power switch must be turned off, the winching handwheel must be inserted into the winching device key shaft, and the winching safety switch must disconnect the safety circuit.

Manual winching operation should be performed by more than 2 people, one person pulls the brake release handle to release the brake, and the other person pulls the winching handwheel to slowly move the car.

Confirm the car level position from the traction rope floor mark, stop the winching, and reset the brake.

3.Traction sheave rope groove wear inspection

Under normal use conditions of the elevator, one or two traction ropes will quickly wear out to the scrap standard, and the depth difference of the traction sheave groove will reach 1.5 mm, and must be replaced or repaired.

The shapes of wheel grooves are divided into V-groove, quick-cut U-groove, and U-groove. The size requirements are configured according to the selected wheel groove type to achieve the working conditions

of the standard friction coefficient.

4.Check the wire rope tension

Use a steel ruler or other measuring tool to measure the height of the spring, and adjust the tension by adjusting the position and height of the spring to keep it flush.

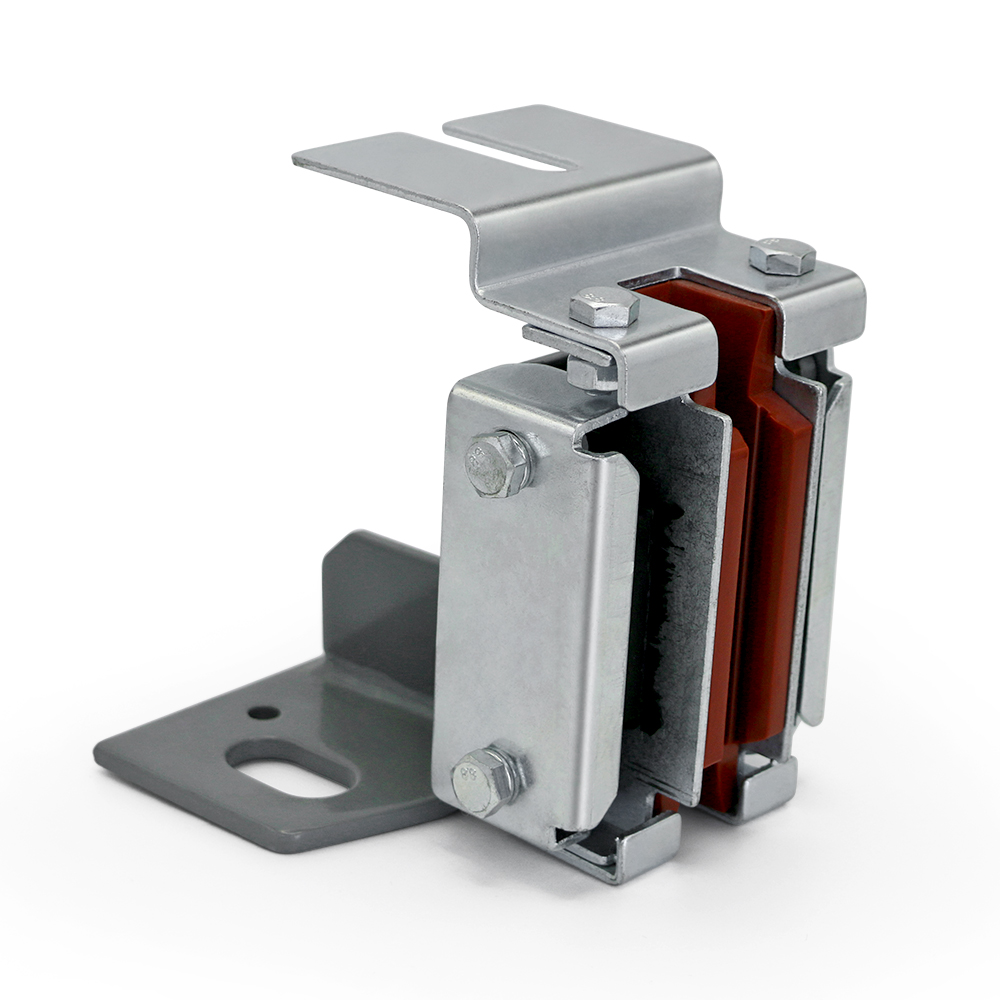

5.Check the gap between the guide shoe and the guide rail

Different guide shoe types have different gap size requirements with the guide rail. The gap between the sliding guide shoe and the fixed guide shoe and the guide rail is 1-2mm, while the gap between the rolling

guide shoe and the guide rail is 3mm. You can use a feeler gauge to measure the gap between the guide shoe and the guide rail.

6.Check the brake clearance

Use a feeler gauge to measure the clearance between 0.2-0.4mm, and both sides need to be checked. To adjust the brake clearance, insert the handle and pull it down. Note that the elevator

cannot run up when pressing down.

7.Verify the function of the limit switch and ultimate switch in the shaft

Press the switch to let the elevator descend. When the elevator fails and continues to descend, the limit switch and ultimate switch slide inward.

8.Leveling accuracy

When the car goes up and down, the leveling detector senses the leveling plate and slowly stops. The horizontal error between the car door sill and the hall door sill in the leveling state is basically

required to be the same. There is no national standard for this size. Generally, the manufacturer requires the error value to be within 3mm.